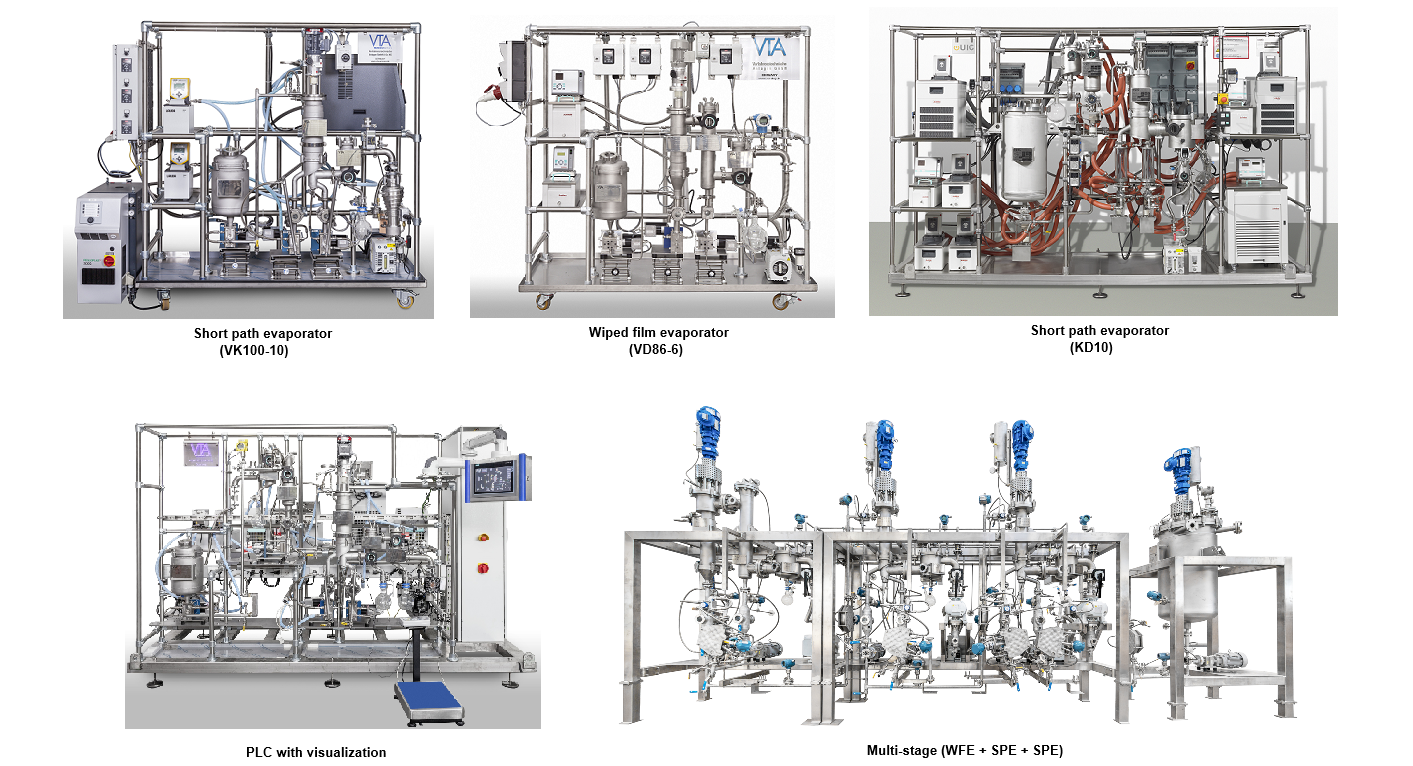

VTA Product line-up

VTA Product line-up| Type | Heated Surface | Feed Rate | Required Crude Amount |

|---|---|---|---|

| [㎡] | [kg/h] | [kg] | |

| Thin Film / Wiped Film | |||

| VD 83-6 | 0.06 | 5.0-12.0 | 30 |

| VD 100-10 | 0.10 | 8.0-20.0 | 50 |

| VD 125-15 | 0.15 | 10.0-35.0 | 100 |

| VD 125-20 | 0.20 | 15.0-40.0 | 100 |

| VD 200-50 | 0.50 | 40.0-100.0 | 300 |

| Horizontal Thin Film | |||

| VDLH 70-4 | 0.04 | 0.1-2.0 | 30 |

| VDH 125-15 | 0.15 | 10.0-35.0 | 100 |

| VDH 125-20 | 0.20 | 15.0-40.0 | 100 |

| VD 200-50 | 0.50 | 40.0-100.0 | 300 |

| Short Path | |||

| VK 83-6 | 0.06 | 3.0-10.0 | 30 |

| VK 100-10 | 0.10 | 3.0-15.0 | 30 |

| VK 125-15 | 0.15 | 8.0-30.0 | 80 |

| VK 200-40 | 0.40 | 25.0-80.0 | 200 |

Larger evaporators on request

UIC Product line-up

UIC Product line-up| Bezeichnung | KD 6 | KD 10 | KD 30 | RF 6 | RF 10 | RF 30 | |

|---|---|---|---|---|---|---|---|

| Feed | kg/h | 3-9 | 5-20 | 15-60 | 3-9 | 5-20 | 15-60 |

| Design* | Short Parth Distillator | Thin Film Evaporator | |||||

| Typical space requirement | m | 2.0×0.8×2.3 | 2.5×1.0×2.5 | 3.0×1.0×3.0 | 2.5×0.8×2.3 | 3.0×1.0×2.5 | 3.5×1.0×3.0 |

| Max. heating temperature | ℃ | 350 | 250 | ||||

| Min. pressure | mbar | 0.001 | 1 | ||||